Fermentation

Fermentation

The hopped wort needs to be filtered and cooled before the yeast can be added and it is drained into another vessel, similar to the mash tun, called a hopback (see picture, right). As the name suggests, this is where the hops are held back and after the liquid has moved on to the next stage, the hops can be removed from the hopback to be used as fertilizer - yet another by-product of brewing.

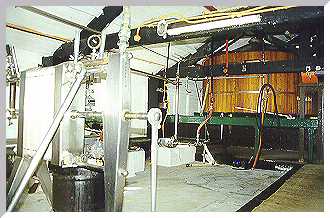

Cooling down to 17ºC is achieved by passing the hopped wort through a paraflow and when this is complete it is time for the hopped wort to be run into large, square, copper-lined tanks called fermenting vessels (see picture, left).

Temperature control is crucial during fermentation to obtain the right balance between alcohol and the desired flavour. The brewer achieves this by passing chilled water through coils in the fermenter and preventing excessive heat which could damage the yeast and spoil the beer. This is when the yeast, which turns the sugar into alcohol and produces carbon dioxide in the process, can be added. CO2 rises to the top and at first causes the beer to form a rocky head. But this soon turns creamy and the beer continues to ferment for up to five days before it is pumped into casks.

This is when the yeast, which turns the sugar into alcohol and produces carbon dioxide in the process, can be added. CO2 rises to the top and at first causes the beer to form a rocky head. But this soon turns creamy and the beer continues to ferment for up to five days before it is pumped into casks.

| Previous Page... | Read More... |